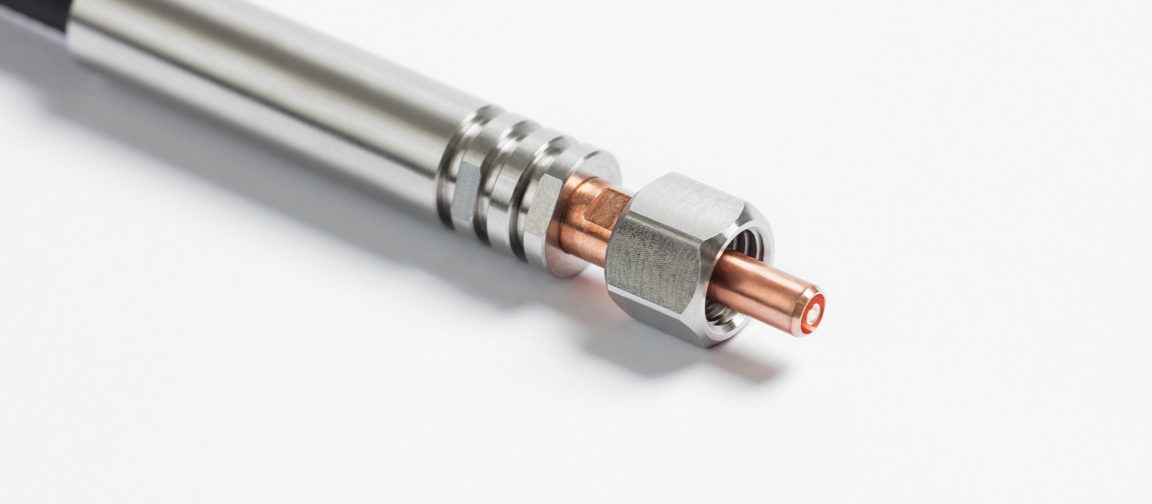

A fiber cable is a single fiber assembly terminated with standard connectors or custom-made ferrules and an application-suitable protection tube.

Lightguide supplies custom-made standard fiber cables and high-power cables that are designed and assembled to ensure the best performance for the desired application.

The silica/silica step-index multi-mode fibers we produce and utilize in our fiber assembly manufacturing processes can be used for:

Our team will help you select the best fiber for the wavelengths you need, allowing you to specify the fiber structure and used materials, the thickness of the F-doped reflecting cladding, and the numerical aperture (NA) of the fiber, all in line with the special conditions and requirements of your application.

Lightguide is a vertically integrated company, which gives you the freedom to create assembly that is designed together with you and that will be a perfect fit for your spectrometer. Lightguide handles everything from design to production, allowing us to produce and deliver in a short period of time. We carry out all critical-to-customer steps inhouse, including:

Meyona provides high quality products, along with proffesional consultancy, reliable technical support and excellent service for some of the most reputable hospitals, clinics and IVF centers in Bulgaria, Macedonia and Kosovo.